NOx Abatement Systems are a crucial aspect of emissions control and air pollution management. NOx, which stands for nitrogen oxides, refers to a group of harmful gases composed primarily of nitric oxide (NO) and nitrogen dioxide (NO2). These gases are produced by combustion processes such as in vehicle engines, power plants, industrial facilities, and heating systems. They contribute to the formation of smog and can have detrimental effects on human health and the environment.

One unique fact about NOx Abatement Systems is that they employ various technologies to reduce the levels of nitrogen oxides emitted into the atmosphere. These technologies can include selective catalytic reduction (SCR), lean burn combustion, and exhaust gas recirculation (EGR), among others. Each system has its specific advantages and effectiveness in reducing NOx emissions. For instance, SCR systems use a catalyst to convert nitrogen oxides into nitrogen and water, making them highly efficient in air pollution control. On the other hand, lean burn combustion systems reduce NOx emissions by lowering the combustion temperature and creating a lean fuel-to-air ratio.

In the upcoming sections of this article, we will delve deeper into the key takeaways of NOx Abatement Systems and explore their significant impacts on emission reduction, environmental protection, and regulatory compliance. We will discuss the benefits of using these systems in different contexts, including vehicle fleets, power generation, and industrial processes. Additionally, we will examine the challenges faced in implementing NOx Abatement Systems and the potential future advancements in this field. Stay tuned to discover how NOx Abatement Systems can play a pivotal role in addressing air pollution issues and ushering in a cleaner, more sustainable future.

Key Takeaways

1. NOx abatement systems are crucial for reducing harmful nitrogen oxide emissions in industrial processes, power plants, and transportation.

2. There are various types of NOx abatement systems available, including selective catalytic reduction (SCR), selective non-catalytic reduction (SNCR), and flue gas recirculation (FGR).

3. SCR systems utilize a catalyst to convert NOx into harmless nitrogen and water vapor, while SNCR systems inject ammonia or urea into the flue gas to chemically react and reduce NOx.

4. FGR systems lower NOx emissions by recirculating a portion of the flue gas back into the combustion process, which reduces the flame temperature and limits the formation of nitrogen oxides.

5. NOx abatement systems play a critical role in meeting environmental regulations and standards, improving air quality, and mitigating the negative impact of nitrogen oxide emissions on human health and the environment.

What are the best NOx Abatement Systems to reduce emissions effectively?

NOx Abatement Systems: An Overview

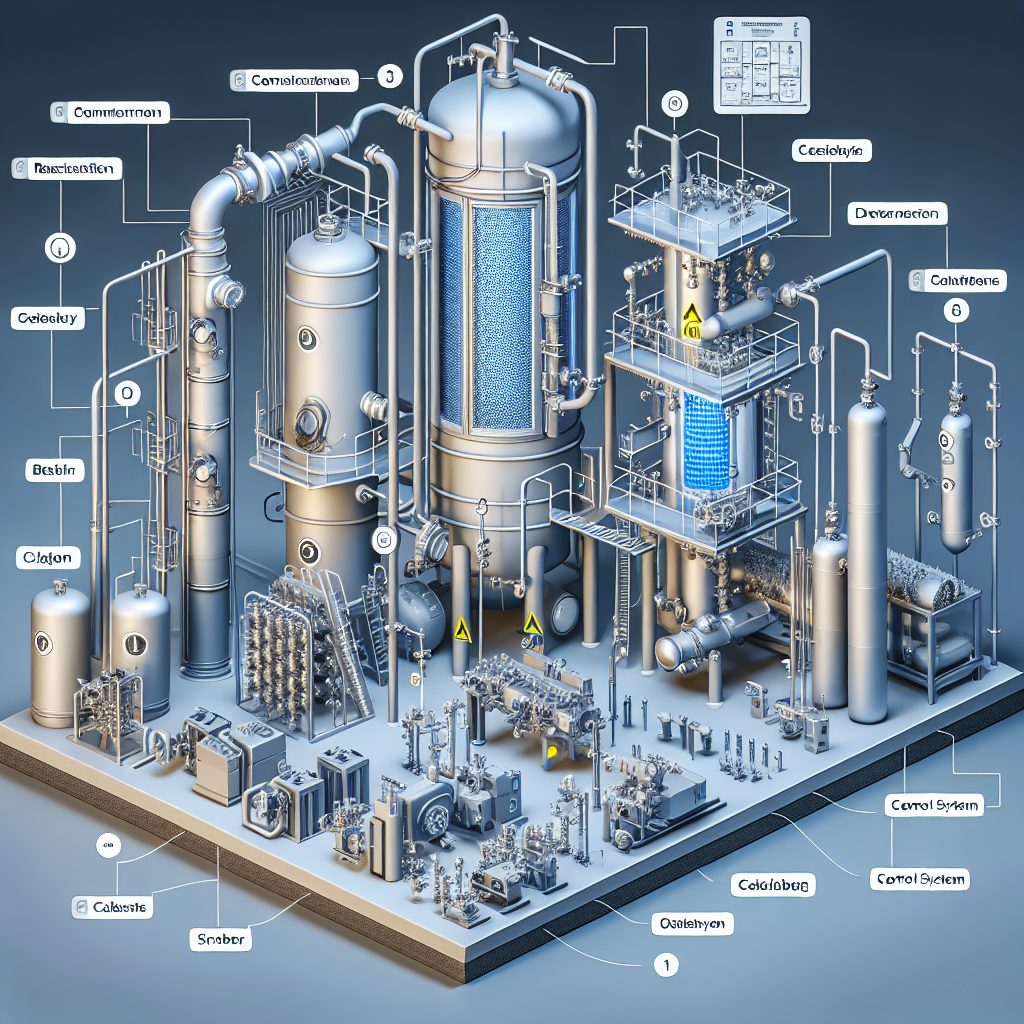

NOx Abatement Systems are advanced technologies designed to reduce nitrogen oxide (NOx) emissions, which are harmful pollutants generated by various industrial processes and combustion engines. These systems play a crucial role in mitigating air pollution and achieving regulatory compliance.

1. Selective Catalytic Reduction (SCR) Systems

SCR systems are widely used in industries that emit significant amounts of NOx. This technology utilizes a catalyst to convert NOx into harmless nitrogen gas and water vapor through a chemical reaction with ammonia or urea injection. SCR systems offer high NOx removal efficiency, making them an effective solution for large-scale emissions reduction.

2. Exhaust Gas Recirculation (EGR) Systems

EGR systems work by recycling a portion of the exhaust gas back into the engine’s combustion chamber. By diluting the oxygen concentration, EGR reduces the formation of NOx during combustion. This system is commonly utilized in diesel engines and is an effective method for reducing emissions without compromising engine performance and efficiency.

3. Non-Thermal Plasma (NTP) Systems

NTP systems use ionized gas to break down NOx molecules into separate nitrogen and oxygen atoms, which subsequently recombine into harmless compounds. This technology can be applied in various applications, including stationary sources like power plants and mobile sources like vehicles. NTP systems provide high NOx removal efficiency, especially for smaller-scale applications.

4. Lean Burn Techniques

Lean burn combustion is an approach that involves running engines with a higher air-to-fuel ratio. By maintaining a lean mixture, the combustion temperature decreases, resulting in lower NOx emissions. This method is commonly used in gas turbines and lean-burn engines and offers effective NOx reduction while ensuring efficient fuel utilization.

5. Hybrid NOx Abatement Systems

Hybrid systems combine multiple NOx reduction technologies to achieve even greater emission reduction efficiency. These systems often integrate SCR, EGR, and NTP technologies to capitalize on their individual strengths. Hybrid systems are versatile and can be tailored to suit specific industrial processes or engine types, making them a comprehensive solution in emissions control.

6. Regular Maintenance and Monitoring

To ensure the continued effectiveness of NOx Abatement Systems, regular maintenance and monitoring are crucial. It is essential to perform routine inspections, cleanings, and necessary repairs to keep the systems operating optimally. Monitoring NOx emissions levels and system performance allows for timely adjustments and proactive measures to maintain compliance with environmental regulations.

7. Optimal System Design and Installation

When implementing NOx Abatement Systems, proper system design and installation are key factors in achieving optimal performance. Working closely with experienced engineers and consultants ensures that the system is tailored to the specific requirements of the industry or engine. This includes selecting the right components, determining the optimum system size, and considering factors such as flow rates, temperatures, and operating conditions.

8. Training and Education

Providing operators and maintenance personnel with proper training and education is vital to maximize the effectiveness of NOx Abatement Systems. Understanding the system’s functions, components, and regular maintenance procedures allows for improved efficiency, early detection of issues, and timely resolution. Training programs can be customized based on the specific type of abatement system employed and the targeted industry or engine application.

9. Government Regulations and Incentives

Governments across the globe have implemented strict regulations and emission standards to combat air pollution and promote sustainable practices. Staying informed about the applicable regulations and understanding available incentives can help companies choose the most suitable NOx Abatement Systems and ensure compliance. Additionally, taking advantage of government incentives may provide financial benefits for implementing advanced emission reduction technologies.

10. Continuous Research and Development

The field of NOx Abatement Systems is continuously evolving as new technologies and methods are researched and developed. Keeping up with the latest advancements helps industries and engine manufacturers stay ahead in reducing emissions and improving overall environmental performance. Collaborating with research institutions and engaging in industry forums or associations contributes to staying informed and participating in the development of more efficient and cost-effective solutions.

Conclusion:

NOx Abatement Systems play a crucial role in reducing harmful nitrogen oxide emissions. By utilizing technologies such as SCR, EGR, NTP, lean burn techniques, and hybrid systems, companies and industries can effectively mitigate NOx emissions while ensuring compliance with environmental regulations. Proper maintenance, optimal system design, training, and awareness of government regulations further enhance the efficacy of these systems. Continual research and development ensure that NOx abatement technologies evolve towards greater efficiency and sustainability.

Ready to reduce NOx emissions? Follow these tips:

- Which NOx Abatement System is best suited for your industry or engine application?

- Are you aware of the maintenance requirements for your chosen NOx Abatement System?

- Have you considered the regulations and incentives provided by your government?

- Are your operators and maintenance personnel properly trained on the system?

- Stay updated with the latest research and advancements in NOx Abatement Systems.

Frequently Asked Questions about NOx Abatement Systems

1. What is a NOx Abatement System?

A NOx Abatement System is a technology designed to reduce the emission of nitrogen oxides (NOx) from various industrial processes, such as power plants, factories, and vehicles. It utilizes different techniques and equipment to convert or remove NOx gases from exhaust emissions, thereby minimizing their harmful impact on the environment.

2. Why is it important to use NOx Abatement Systems?

NOx gases contribute to air pollution and have detrimental effects on human health and the environment. By implementing NOx Abatement Systems, we can significantly reduce the release of these harmful gases, ensuring cleaner air and a healthier living environment for all.

3. How do NOx Abatement Systems work?

NOx Abatement Systems employ various methods, such as selective catalytic reduction (SCR), non-selective catalytic reduction (NSCR), or exhaust gas recirculation (EGR), to reduce the formation and release of NOx in combustion processes. These techniques involve the use of catalysts, additives, or recirculated exhaust gases to convert or remove NOx molecules.

4. Can NOx Abatement Systems be retrofitted into existing industrial equipment?

Yes, NOx Abatement Systems can be retrofitted into existing industrial equipment to improve their environmental performance. However, it is essential to consult with experienced engineers or specialists to assess the feasibility and compatibility of retrofitting NOx Abatement Systems into specific equipment.

5. Do NOx Abatement Systems require any maintenance?

Yes, like any other mechanical or chemical system, NOx Abatement Systems require regular maintenance to ensure their optimal efficiency. This may include inspecting and cleaning catalysts, replacing filters or additives, and monitoring system performance to identify and address any issues promptly.

6. Are there any incentives or regulations promoting the use of NOx Abatement Systems?

Yes, many governments and environmental agencies worldwide have implemented regulations to control and reduce NOx emissions. Incentives, such as tax credits or grants, are often offered to businesses or industries that adopt NOx Abatement Systems or comply with emission reduction standards.

7. Can NOx Abatement Systems eliminate 100% of NOx emissions?

While NOx Abatement Systems can achieve significant reductions in NOx emissions, achieving complete elimination of NOx gases is challenging. Factors like the type of technology used, the age of equipment, and the operational conditions can affect the overall efficiency of NOx Abatement Systems.

8. Are NOx Abatement Systems cost-effective?

Implementing NOx Abatement Systems may incur initial costs for installation and ongoing maintenance. However, in the long run, they can lead to cost savings through improved energy efficiency, compliance with emission regulations, and reduced health and environmental impacts.

9. What industries or sectors benefit from NOx Abatement Systems?

Various industries, including power generation, chemical plants, refineries, cement production, and transportation sectors (such as shipping and trucking), can benefit from implementing NOx Abatement Systems. Any industry that relies on combustion processes that generate NOx emissions can significantly reduce their environmental footprint through the use of these systems.

10. Can NOx Abatement Systems be customized based on specific needs?

Yes, NOx Abatement Systems can be customized to suit specific industry needs and operational requirements. Factors like the type of combustion process, emission levels, system capacity, and space availability can all be considered when designing and implementing a tailored NOx Abatement System.

Final Thoughts – NOx Abatement Systems

NOx Abatement Systems play a crucial role in combating air pollution and reducing the adverse effects of nitrogen oxides on our environment and health. By implementing these systems, industries can actively contribute to a cleaner and greener future.

While the initial costs and maintenance requirements of NOx Abatement Systems may seem daunting, their long-term benefits far outweigh these challenges. Improved air quality, compliance with environmental regulations, and even potential cost savings make NOx Abatement Systems a worthwhile investment.