NOx Abatement Technologies refer to a set of strategies and technologies aimed at reducing the emissions of nitrogen oxides (NOx) from various combustion processes. Nitrogen oxides are a group of highly reactive gases that are released into the atmosphere during the burning of fossil fuels, such as gasoline, coal, and natural gas. These emissions contribute to air pollution and have detrimental effects on human health and the environment.

One particular impact of NOx emissions is their role in the formation of smog and ground-level ozone, both of which pose significant risks to human health. Smog can cause respiratory problems, such as asthma and bronchitis, and worsen existing conditions, while ground-level ozone can irritate the respiratory system and impair lung function. Additionally, nitrogen oxides can also react with other compounds in the atmosphere to form acid rain, which can damage ecosystems and harm aquatic life.

In this article, we will explore some of the key technologies and strategies used for NOx abatement. We will discuss the effectiveness of these methods in reducing emissions, their potential drawbacks, and their applicability to different industries. Furthermore, we will delve into the importance of adopting NOx abatement technologies in a broader context, considering the global efforts to combat climate change and improve air quality. Let’s now explore the key takeaways in detail to gain insights into this crucial subject matter.

Key Takeaways

1. NOx abatement technologies play a crucial role in reducing nitrogen oxide emissions, a major contributor to air pollution and climate change, by employing various methods to eliminate or convert NOx into less harmful substances.

2. Selective Catalytic Reduction (SCR) is a widely used NOx abatement technology that utilizes a catalyst to convert NOx into nitrogen and water vapor, reducing emissions by up to 90%.

3. Exhaust Gas Recirculation (EGR) is another effective technique that recirculates a portion of exhaust gases back into the combustion process, lowering temperatures and reducing NOx formation by up to 65%.

4. NOx abatement technologies also include non-catalytic methods such as fuel injection, which involves injecting a small amount of fuel into the combustion chamber after the main combustion event to thermally reduce NOx formation.

5. With evolving regulations and increasing environmental concerns, the development and implementation of advanced NOx abatement technologies are crucial for achieving cleaner air, combating climate change, and improving public health.

What are the most effective NOx Abatement Technologies?

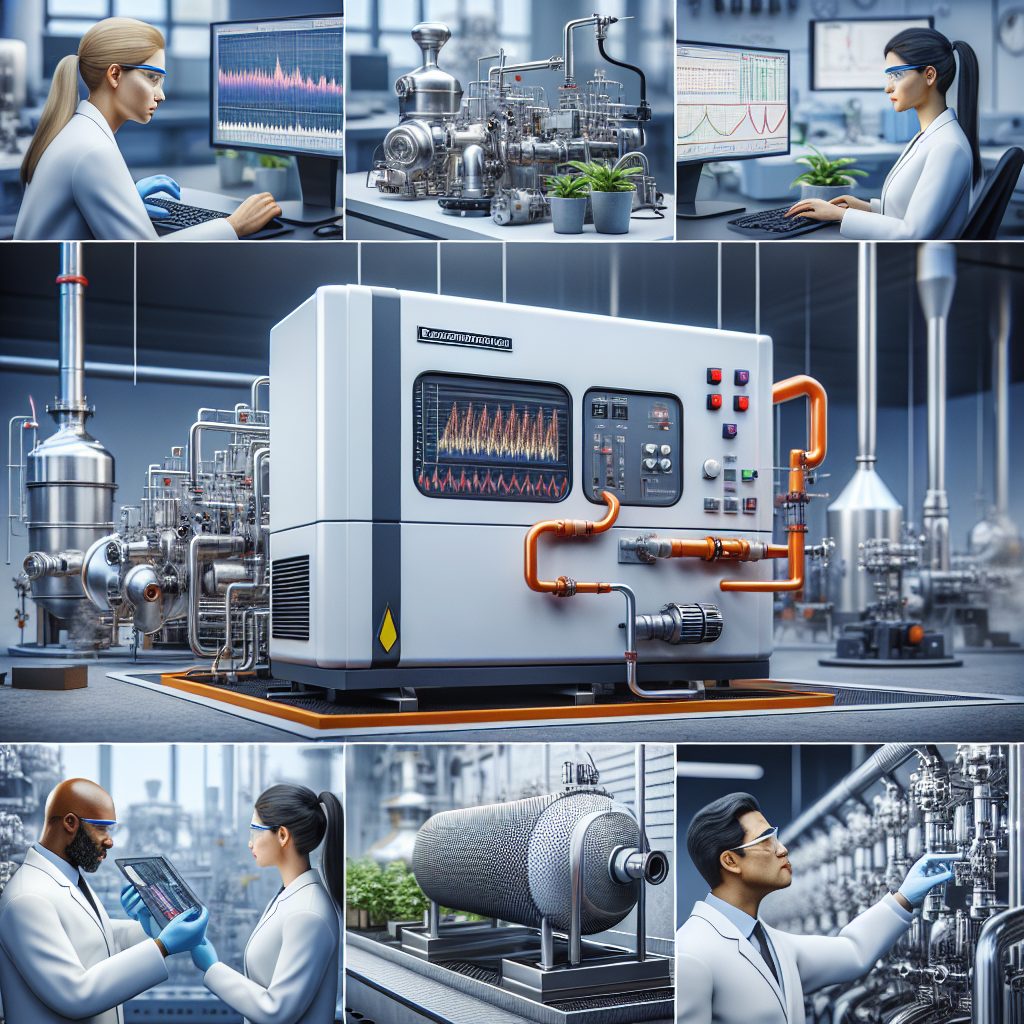

1. Selective Catalytic Reduction (SCR)

Selective Catalytic Reduction is a widely used NOx abatement technology in various industries, including power plants and automotive. SCR systems utilize a catalyst to convert harmful nitrogen oxides (NOx) into harmless nitrogen gas (N2) and water vapor by reacting with ammonia or urea. The process occurs in a high-temperature environment, typically in the range of 300-400°C. SCR technology offers high efficiency in reducing NOx emissions, often exceeding 90%.

2. Exhaust Gas Recirculation (EGR)

Exhaust Gas Recirculation is another effective NOx abatement technology commonly employed in combustion engines. It works by recirculating a portion of the exhaust gases back into the combustion chamber, diluting the oxygen concentration and reducing peak combustion temperatures. Lower temperatures lead to reduced formation of NOx during the combustion process. EGR systems can achieve NOx reduction levels of up to 70% without compromising engine performance.

3. Low-NOx Burners

Low-NOx burners are specifically designed to minimize the formation of nitrogen oxides during the combustion of fuels. They achieve this by creating fuel-rich zones, reducing peak flame temperatures, and improving the mixing of fuel and air. These burners are commonly used in industrial furnaces, boilers, and heaters. Low-NOx burners can reduce NOx emissions by up to 50% compared to conventional burners.

4. Fuel Additives

Fuel additives offer an alternative approach to NOx abatement technologies. These chemical compounds, when added to the fuel, promote cleaner combustion and help reduce NOx formation. Common fuel additives for NOx reduction include ammonia-based compounds, such as ammonia water or ammonia salts. When properly applied, fuel additives can lead to significant NOx reduction levels, especially in stationary sources like power plants.

5. Burner Modifications

Modifying the burner design and operation parameters can also contribute to NOx reduction. Several techniques, such as staged combustion, lean premixed combustion, and flue gas recirculation, can be implemented to minimize the formation of nitrogen oxides. These modifications involve controlling the fuel-air ratio, optimizing combustion dynamics, and enhancing mixing processes. Burner modifications can achieve NOx reduction levels of up to 60% in certain applications.

6. Non-Thermal Plasma

Non-Thermal Plasma (NTP) technologies offer innovative solutions for NOx abatement. These systems utilize electrical discharges to convert NOx into nitrogen and oxygen through reactions with various chemical species. NTP technologies can be applied to both stationary and mobile sources and have shown promising results in reducing NOx emissions. However, they require complex setup and maintenance and are typically employed in specific industrial applications.

7. Tips for Effective NOx Abatement:

- Regularly monitor and maintain NOx abatement systems to ensure optimal performance and efficiency.

- Consider a combination of different NOx abatement technologies for maximum effectiveness in specific applications.

- Implement proper training programs for operators to guarantee safe and efficient operation of NOx abatement equipment.

- Stay updated with the latest advancements and regulations regarding NOx abatement to comply with environmental standards.

- Engage in continuous improvement and research to identify new and more efficient NOx abatement technologies.

Frequently Asked Questions

1. What are NOx Abatement Technologies?

NOx Abatement Technologies are systems or methods designed to reduce nitrogen oxide (NOx) emissions from various industrial processes and combustion sources. These technologies help in compliance with environmental regulations and promote cleaner air quality.

2. How do NOx Abatement Technologies work?

NOx Abatement Technologies work by employing different strategies to reduce NOx emissions. Common methods include selective catalytic reduction (SCR), non-selective catalytic reduction (NSCR), low-NOx burners, and exhaust gas recirculation (EGR). These techniques aim to convert and eliminate NOx compounds present in exhaust gases.

3. What are the benefits of using NOx Abatement Technologies?

Using NOx Abatement Technologies brings numerous benefits, including improved air quality, reduced environmental impact, and compliance with emission standards set by regulatory authorities. Additionally, these technologies can enhance the efficiency of combustion systems, resulting in energy savings and cost reduction.

4. Are NOx Abatement Technologies applicable to all industries?

Yes, NOx Abatement Technologies can be applied in various industries, including power generation, manufacturing, refineries, chemical processing, and automotive. Different industries may require specific technologies tailored to their operational needs and emission characteristics.

5. Are NOx Abatement Technologies expensive to implement?

The cost of implementing NOx Abatement Technologies can vary depending on factors such as the size of the facility, the specific technology employed, and the compliance requirements. While initial investment costs may be involved, many organizations find that the long-term benefits, such as improved efficiency and regulatory compliance, outweigh the initial expenses.

6. Can NOx Abatement Technologies be retrofitted to existing systems?

Yes, NOx Abatement Technologies can often be retrofitted to existing systems. Retrofits may involve modifications to combustion processes, the installation of emission control devices, or the addition of catalysts. Consulting with experts and conducting a thorough assessment of the existing system can determine the feasibility of retrofitting NOx Abatement Technologies.

7. Are there any regulatory requirements for NOx emissions?

Yes, regulatory bodies enforce emissions limits for NOx in numerous regions worldwide. Compliance with these regulations is necessary to avoid penalties and legal consequences. Implementing NOx Abatement Technologies assists industries in meeting the required standards and maintaining environmental sustainability.

8. Can NOx Abatement Technologies be customized for specific emission control needs?

Yes, NOx Abatement Technologies can be customized to address specific emission control needs. Manufacturers and suppliers of these technologies often offer flexible solutions that can be tailored to an industry’s emission characteristics, operational conditions, and regulatory requirements.

9. Do NOx Abatement Technologies have any impact on energy efficiency?

Yes, NOx Abatement Technologies can impact energy efficiency. Many NOx reduction techniques, such as SCR and low-NOx burners, strive to optimize combustion processes, resulting in enhanced energy utilization. Improved energy efficiency can lead to reduced fuel consumption, lower operational costs, and decreased greenhouse gas emissions.

10. Can NOx emissions be completely eliminated?

While NOx Abatement Technologies can significantly reduce NOx emissions, complete elimination is challenging. However, the implementation of advanced technologies combined with stringent control measures can achieve substantial reductions, enabling industries to operate with minimal environmental impact.

Final Thoughts on NOx Abatement Technologies

NOx Abatement Technologies play a pivotal role in combatting air pollution and ensuring sustainable industrial practices. By employing these technologies, industries can contribute to cleaner air, reduced environmental degradation, and improved public health. It is crucial for organizations to stay informed about the latest advancements in NOx Abatement Technologies, as well as regulatory requirements, to effectively implement and maintain these solutions.

Moreover, the continued research and development in NOx Abatement Technologies hold promise for even more efficient and effective systems in the future. As technology evolves, we can anticipate further advancements in reducing NOx emissions, enhancing energy efficiency, and promoting overall environmental sustainability. By prioritizing the adoption of NOx Abatement Technologies, industries can demonstrate their commitment to a greener future and pave the way for a cleaner, healthier planet.