NOx Reduction Technologies refers to a set of techniques and strategies aimed at reducing nitrogen oxides (NOx) emissions from various industrial processes and transportation sources. Nitrogen oxides are a group of harmful pollutants that contribute to air pollution and environmental degradation. With the increasing concern over the detrimental effects of these emissions on human health and the environment, the development and implementation of NOx reduction technologies have become crucial.

One unique fact about NOx Reduction Technologies is that they play a significant role in addressing air pollution from combustion-related sources such as power plants, vehicles, and industrial processes. These technologies encompass a range of approaches, including exhaust gas recirculation (EGR), selective catalytic reduction (SCR), and lean burn combustion technologies, to name a few. Each approach tackles NOx emissions differently, based on the specific source and technology utilized.

In the forthcoming sections of this article, we will explore some key takeaways related to NOx Reduction Technologies. We will delve into the specific impacts of these technologies on air pollution reduction and environmental protection. Additionally, we will discuss their implementation challenges, cost considerations, and notable success stories. By the end, readers will have a comprehensive understanding of the importance and potential of NOx Reduction Technologies in creating a cleaner and healthier environment.

Key Takeaways

1. Combustion modifications are effective in reducing NOx emissions, with techniques such as low NOx burners, staged combustion, and flue gas recirculation proving successful.

2. Post-combustion controls, such as selective catalytic reduction (SCR) and selective non-catalytic reduction (SNCR), can further reduce NOx emissions by treating the flue gas after it has been generated.

3. Ammonia-based SCR systems are highly efficient in NOx removal, whereas SNCR systems provide flexibility and cost-effectiveness, particularly in smaller applications.

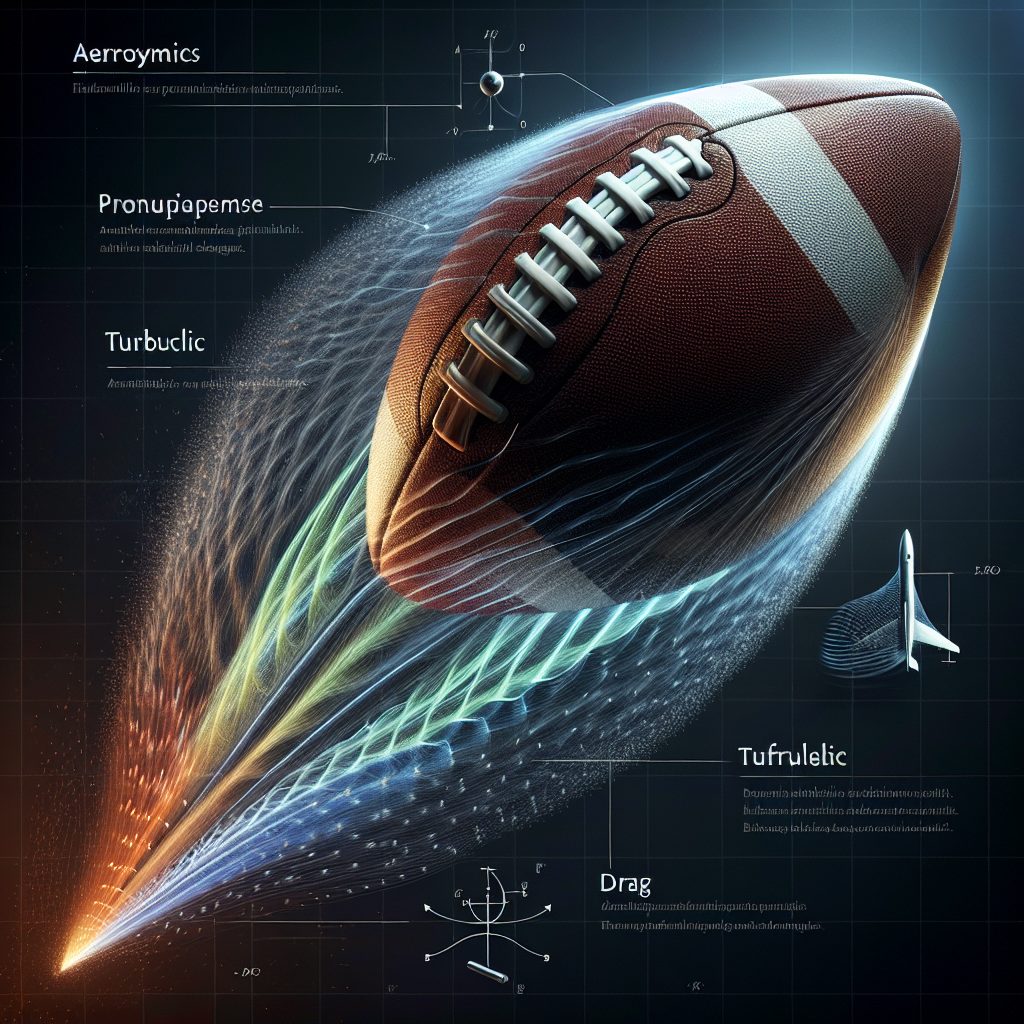

4. Improved engine design and advanced technologies, like lean-burn combustion and exhaust gas recirculation, offer significant NOx reduction potential in transportation and mobile sources.

5. Proper maintenance and optimization of NOx reduction technologies are crucial to ensure long-term effectiveness, necessitating continuous monitoring, system upgrades, and adherence to emission standards.

What are the Best NOx Reduction Technologies for Emissions Control?

1. Selective Catalytic Reduction (SCR)

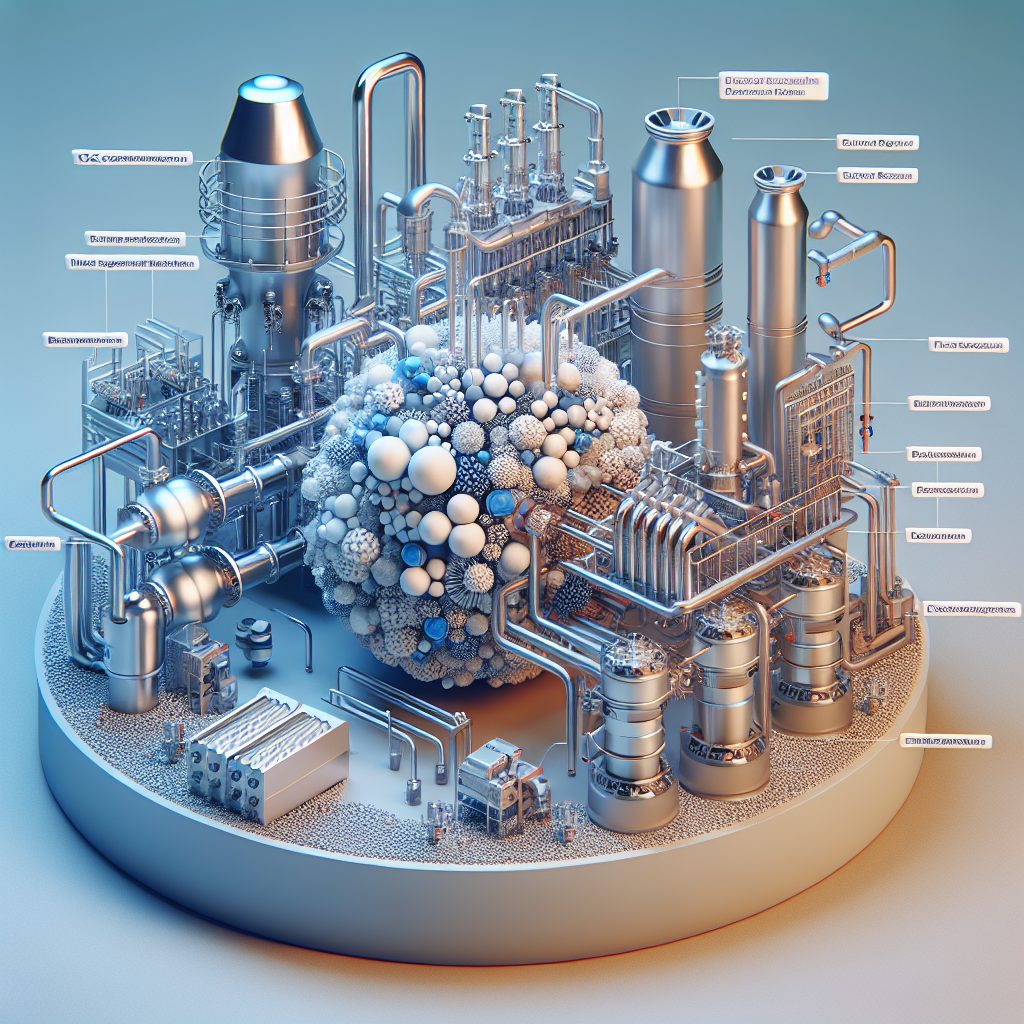

Selective Catalytic Reduction (SCR) is a widely recognized technology for reducing NOx emissions. It involves injecting a reductant, usually ammonia or urea, into the exhaust gas stream, which then reacts with the NOx over a catalyst to form harmless nitrogen (N2) and water vapor (H2O). SCR systems are highly effective, achieving up to 90% NOx reduction rates.

2. Exhaust Gas Recirculation (EGR)

Exhaust Gas Recirculation (EGR) is another commonly used NOx reduction technology. It works by recirculating a portion of the engine’s exhaust gas back into the combustion chamber, which reduces the oxygen concentration and lowers the combustion temperature. This results in decreased NOx formation during the combustion process. EGR systems can achieve significant NOx reduction while improving fuel efficiency.

3. Lean NOx Trap (LNT)

The Lean NOx Trap (LNT) is a technology that utilizes a catalyst to store NOx from the exhaust gas in lean-burn conditions, and then periodically release and reduce the stored NOx to harmless gases under rich-burn conditions. LNT systems are effective at lower temperatures but might face durability challenges due to sulfur poisoning.

4. Gasoline Direct Injection (GDI)

Gasoline Direct Injection (GDI) is a technology commonly used in gasoline engines to improve fuel efficiency. While primarily aimed at reducing carbon emissions, GDI also contributes to NOx reduction through its optimized combustion process. GDI systems precisely control the injection of fuel, resulting in lower combustion temperatures and reduced NOx formation.

5. Non-Thermal Plasma (NTP)

Non-Thermal Plasma (NTP) technology involves passing exhaust gas through a plasma discharge, which creates chemically reactive species. These reactive species then effectively oxidize and reduce NOx into harmless gases. NTP systems are particularly valuable for reducing NOx in lean burn conditions and have the potential to achieve high NOx removal efficiencies.

6. Low-NOx Burners

Low-NOx burners are commonly used in industrial applications, particularly in combustion processes that involve fossil fuels. These burners are designed to minimize the formation of NOx by carefully controlling fuel and air mixing, ensuring complete combustion, and reducing flame temperature. The use of low-NOx burners can significantly reduce NOx emissions from industrial sources.

7. Aftertreatment Systems

Aftertreatment systems are utilized in various vehicle applications to treat exhaust gases and reduce NOx emissions. These systems typically combine multiple NOx reduction technologies, such as SCR and Diesel Particulate Filters (DPF), to achieve optimal emission control. Aftertreatment systems are designed to be efficient, durable, and compliant with strict emission standards.

8. Guides for Implementing NOx Reduction Technologies

1. Assess your specific emission control requirements and consult with experts in the field to determine the most suitable NOx reduction technology for your application.

2. Consider the size, capacity, and operational conditions of your equipment or vehicles when selecting NOx reduction technologies to ensure optimal performance.

3. Evaluate the costs and potential benefits of implementing NOx reduction technologies, including fuel savings, compliance with emission regulations, and environmental impact.

4. Regularly monitor and maintain the NOx reduction systems in your equipment or vehicles to ensure sustained performance and compliance.

5. Stay updated with the latest advancements in NOx reduction technologies and explore opportunities for continuous improvement in emission control.

Frequently Asked Questions

1. What are NOx Reduction Technologies?

NOx Reduction Technologies refer to a range of methods and technologies used to minimize the emission of nitrogen oxides (NOx) from various sources, such as industrial plants, vehicles, and power generation facilities.

2. Why is reducing NOx emissions important?

Reducing NOx emissions is crucial because these compounds contribute to air pollution, smog formation, and adverse health effects. Moreover, NOx is a greenhouse gas that significantly contributes to climate change.

3. What are some common NOx Reduction Technologies?

Common NOx Reduction Technologies include selective catalytic reduction (SCR), exhaust gas recirculation (EGR), low NOx burners, flue gas treatment systems, and lean burn combustion techniques.

4. How does selective catalytic reduction (SCR) work?

SCR employs a catalyst to convert NOx gases into harmless nitrogen (N2) and water (H2O) through a chemical reaction using a reducing agent, typically ammonia or urea. This technology is widely used in power plants, diesel engines, and industrial furnaces.

5. Are NOx Reduction Technologies effective in reducing emissions?

Yes, NOx Reduction Technologies have proven to be highly effective in reducing NOx emissions. Depending on the technology used, emission reductions of up to 90% can be achieved, leading to improved air quality and environmental protection.

6. Are NOx Reduction Technologies expensive?

While the costs vary based on the specific technology and application, implementing NOx Reduction Technologies can require significant investments. However, the long-term benefits, such as compliance with emission regulations, improved public health, and energy savings, often outweigh the initial costs.

7. Can NOx Reduction Technologies be retrofitted into existing plants and vehicles?

Yes, many NOx Reduction Technologies can be retrofit into existing plants and vehicles. Retrofitting allows older facilities to comply with current emission regulations without requiring complete equipment replacement.

8. Is there any trade-off between reducing NOx emissions and energy efficiency?

In some cases, there may be a slight trade-off between reducing NOx emissions and energy efficiency. However, advanced NOx Reduction Technologies aim to minimize this trade-off by optimizing combustion processes and ensuring optimal performance.

9. Do NOx Reduction Technologies have any other environmental benefits?

Yes, besides reducing NOx emissions, many of these technologies also contribute to the reduction of other harmful pollutants, such as particulate matter (PM), sulfur dioxide (SO2), and volatile organic compounds (VOCs).

10. Where can I find more information about NOx Reduction Technologies?

For more in-depth information about NOx Reduction Technologies, it is recommended to consult environmental regulatory agencies, industry publications, research papers, and specialized environmental engineering firms.

Final Thoughts

NOx Reduction Technologies play a crucial role in mitigating air pollution and addressing the environmental challenges associated with nitrogen oxide emissions. As global awareness about the impact of NOx increases, the implementation of these technologies becomes increasingly important. While the initial costs and challenges may be significant, long-term benefits are manifold, including better air quality, improved public health, and a reduced carbon footprint.

As technology continues to advance, we can expect further innovations and improvements in NOx Reduction Technologies, making them more accessible and efficient. To achieve significant reductions in NOx emissions, it is essential for industries, governments, and individuals to embrace and support the adoption of these technologies on a larger scale. By working together, we can create a cleaner and more sustainable future for generations to come.